Shed Terms explained

Shed Terminology |

||||||

|

||||||

|

Shiplap, overlap, pent, apex, reverse apex - what do all these terms mean? We'll talk you through the shed terminology you should know before you start looking into the right shed for you. There is a bewildering array of timber sheds and workshops on the market, so here's a brief breakdown of their main components to help you choose the most suitable type for your needs. This glossary of shed terms is ideal if this is the first time you will be buying a shed. |

|||||

|

It can be difficult to judge which product is best for you, especially when looking online. You need a shed that will suit you and last for many years, so when looking to buy a new shed you want to know the details of what you'll be getting. We explain what the common terms you will come across when buying a shed online to help you make an informed choice, then you just need to find a structure that is the size you require. |

||||||

Types of Shed Wall |

||||||

There are three types of wall, or cladding, available for your garden shed:

|

|

|||||

|

Tongue and groove shedsWalls of this design consist of boards which interlock with each other to give the shed extra strength as well as protection against rainwater. Tongue and groove boards are able to dry more quickly than overlapping ones, which means they are less likely to become warped through water damage. They are supplied with either or shaped roofs. |

|||||

Shiplap shedsThe shiplap design is very similar to tongue and groove - in fact, the terms are often used interchangeably - but includes a lip, or groove, between each board that helps the rain runoff. Like tongue and groove, shiplap is regarded as a sign of good build quality. Both these types are time-consuming to produce, so tend to be more expensive than overlap sheds. To find out more see: Benefits of a shiplap shed or workshop. |

|

|||||

|

Overlap shedsOverlap walls are the most common type of shed cladding. They consist of rough sawn timber boards, with each one partly overlapping the next. Ideally these boards should be at least 8mm thick for good weatherproofing. For more details see: Benefits of an overlap shed or workshop. |

|||||

Timber Treatment used on Sheds |

||||||

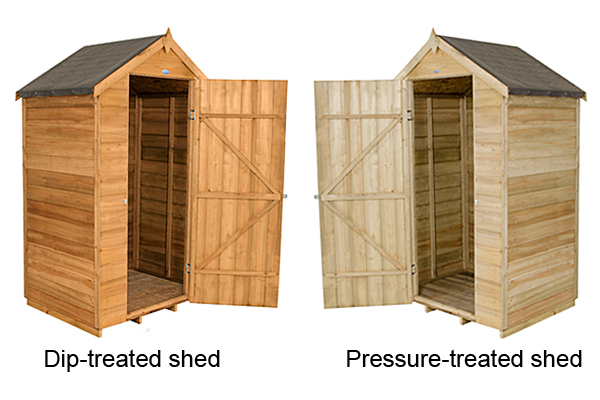

The walls will have been either dip-treated or pressure-treated to guard against rot and fungus. Dip-treated sheds and workshops are normally a golden brown colour and are guaranteed against rot for 10 years as long as they are regularly re-coated with timber preservative. Pressure-treated sheds and workshops usually have a pale green tinge and are guaranteed against rot for 15 years, with no re-coating required during that time. |

|

|||||

|

Most sheds are made up of individual panels ready to screw together. This makes the build relatively quick and easy, and a couple of people with some basic DIY experience should be able to erect a shed in a matter of hours. For a small extra outlay, you can opt to have the shed assembled professionally in your garden if you prefer. |

|||||

|

||||||

Floor and Roof Materials for Sheds |

||||||

|

Shed floors and roofs can be made from either:

|

|||||

OSB shed roofsOSB (oriented strand board), also known as sheet material, is the most widely used component in shed floors and roofs. It consists of man-made panels comprising various types of wood strands which are glued together with a synthetic adhesive. The strands are then pressed together in layers to form large boards. |

|

|||||

|

Timber shed roofsTimber boards are usually made of pine, and provide an attractive, strong and durable type of flooring. They are less prone to absorbing moisture than OSB panels but are more expensive to produce. However, although timber floors cost more initially, you can replace individual planks if they get damaged instead of having to buy a whole new panel as would be the case with OSB. |

|||||

Shed Roof Shape |

||||||

There are two shapes of shed roof available:

|

|

|||||

|

Pent shed roofA pent shed has a single roof section angled at a slope to allow rainwater to drain away. This design offers generous headroom at the front, and there is plenty of space to store long-handled tools and other tall pieces of equipment at the rear. We stock pent sheds with both and walls. |

|||||

| A pent roof is probably also the best option if you are going to place your shed against a house wall or boundary fence. Rainwater will run off the roof away from the wall or fence, avoiding any possible damp issues.

Likewise, if there are height restrictions, perhaps due to overhanging trees, the pent shed is a good solution. Many of the smaller models are also ideal for narrow gardens and alleyways. |

|

|||||

|

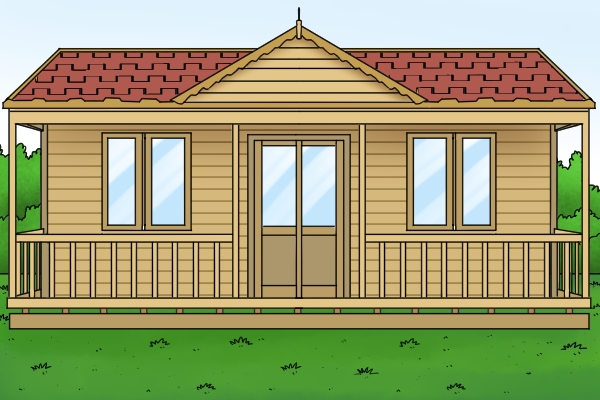

Apex shed roofAn apex shed has a pointed roof consisting of two sections meeting at a ridge in the middle. This gives more height in the centre of the structure to enable you to move around easily. The design has a traditional feel which some people find more attractive than the pent version. This may be important if the shed is going to occupy a prominent position. We supply both and sheds. |

|||||

What's a reverse apex shed roof?This is a shed with an apex roof that has the door set in a side wall instead of the gable end. Many people like the design as it makes it easier to reach all parts of the shed. |

|

|||||

Shed Roof Covering |

||||||

|

To protect them from the elements, shed roofs are normally covered in either:

|

|||||

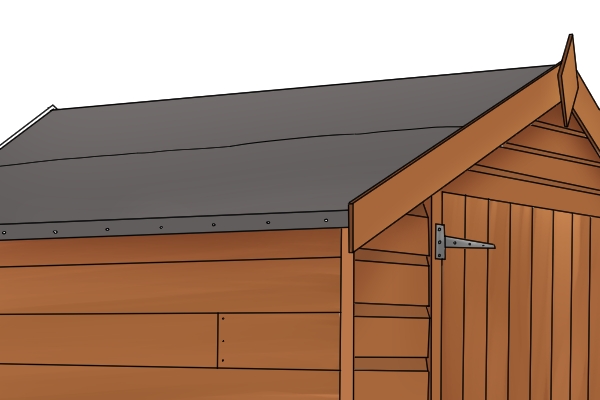

Roofing felt for shedsThis is a waterproof material consisting of paper fibres impregnated with asphalt and given a coating of minerals (green felt) or sand (more lightweight black felt). It's applied to the roof of the shed to make it weatherproof and increase its lifespan. You attach the felt to the roof with a special adhesive and then nail it into place. |

|

|||||

|

If you choose to erect the shed yourself, you may have to cut the felt to fit. However, with some sheds the felt is supplied pre-cut to the correct size and you merely have to secure it in place. For more information see: How to assemble a Forest Garden shed. |

|||||

Onduline sheets for shedsis the brand name for a type of corrugated roofing material made out of cellulose fibres which have been saturated in bitumen. Lightweight and attractive, it provides weatherproof protection for sheds at the premium end of the market and comes in the form of sheets which you fix to the roof with special nails. |

|

|||||

|

Onduline sheets cost more initially than roofing felt but are much more durable, are quick and easy to assemble and come with a 15-year manufacturer's guarantee. | |||||

|

||||||

Shed Doors |

||||||

|

You should think carefully about what you want to use your shed for before selecting a design. Most sheds are available with either single or double doors. The doors can be situated in one of the gable ends of the shed or on one of the side walls. |

|||||

A single door is typically 660mm (26" approx) wide, which is perfectly adequate for getting most garden tools in and out easily. Some premium sheds have doors up to 880mm (almost 36") wide. An important consideration is which side you will want the hinges fixing. Consider any obstructions, to ensure you will be able to fully open the door. |

|

|||||

|

Double doors are particularly useful for easy access to large pieces of equipment such as lawnmowers and wheelbarrows, and also let more light in when you're looking for tools. |

|||||

To make them durable doors are usually braced, which means horizontal supports have been added inside. High-quality sheds often have ledged and braced doors, with two extra beams running diagonally down the door to give superior strength. |

|

|||||

Shed Windows |

||||||

|

For safety and security, sheds are normally supplied with acrylic windows. This is a type of plastic which is frequently referred to as Perspex. While acrylic is the name of the material, Perspex is a brand name which is often used generically. Acrylic is very durable and doesn't crack easily. It also weighs only half as much as glass, is extremely weather-resistant and can withstand low temperatures. |

|||||

| Windows can also be made out of another type of plastic called styrene. This is a low cost, shatter-resistant and lightweight material which, like acrylic, is ideal where safety is a consideration. |  |

|||||

|

Windows that can be opened are good for ventilation and make the shed more versatile - so there is plenty of light for you to make homebrew, pot up plants or tinker with your bike or lawnmower without getting too hot and uncomfortable. | |||||

| Fixed windows that can't be opened are preferred by some people because they are cost-effective, tend to be easier to install than the opening kind when erecting the shed, and also make the building more secure as there is one less point of entry. |  |

|||||

|

Of course, for maximum security, ease of construction and minimum outlay you may choose not to have any windows at all - so your belongings will be out of sight of prying eyes. | |||||

Do you need planning permission for a shed? |

||||||

|

The broad planning rules governing outbuildings, which also apply to sheds and log cabins, are as follows: |

||||||

|

If you want to put up small detached buildings such as a garden shed, summerhouse or log cabin in your garden, building regulations will not normally apply if the floor area of the building is less than 15 square metres (16 square yards) and contains NO sleeping accommodation. | |||||

If the floor area of the building is between 15m2 and 30m2 you will not normally be required to apply for building regulations approval, providing that the building contains no sleeping accommodation and is either at least 1m from any boundary, or is constructed of substantially non-combustible materials. |

|

|||||

|

Please note: the above rules are subject to certain limits and conditions. For more information, click on this link. This is a guide only, and policy throughout the UK may vary. If you're thinking of getting a large shed, it's advisable to check with your Local Planning Authority whether permitted development rights apply – they may have been removed. |

|||||

|

||||||