Benefits of a dip-treated shed or workshop |

||||||

|

||||||

What is dip treatment? |

||||||

|

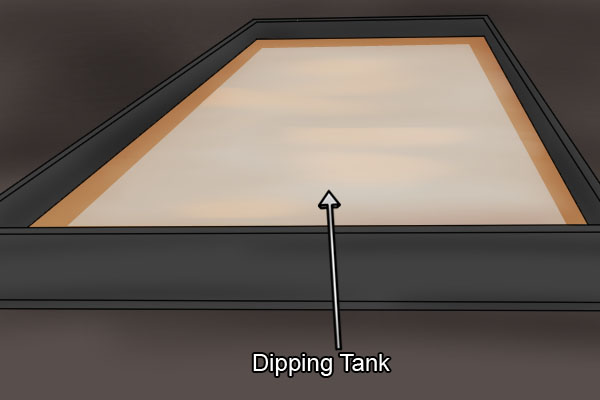

Dip treatment is the most common method of applying preservative to timber in bulk. With this technique, all the wooden components that will make up the shed are dipped into a tank of either water-based or solvent-based preservative before the panels are put together. |

|||||

What are the advantages? |

||||||

Time-savingDip treating achieves a similar result to brushing or spraying the preservative on to the shed, but is carried out in advance at the factory – saving buyers time and effort. |

|

|||||

|

AffordableThe dip-treating process is quicker, simpler and less expensive to carry out than pressure-treating (also known as tanalising). Labour and storage costs are lower, making this type of shed popular and affordable. |

|||||

AttractiveDip-treated sheds typically come in a rich reddish gold colour. This is because the timber derives mostly from British redwoods, which can vary in tone. A cedar-red dye is therefore applied during manufacture to ensure that every plank of wood takes on the same colour. This will gradually fade until the timber is re-treated. |

|

|||||

|

Wide choiceBecause dip-treated timber is used to make the majority of sheds and workshops in the UK, there is a huge range of different shapes, sizes and specifications for buyers to choose from. We stock a wide variety of dip-treated sheds with both apex and pent roof styles, ranging from a model up to a roomy with double doors. |

|||||

Environmentally friendlyForest Garden sheds are coated in water-based preservative, which is kinder to the environment than solvent-based treatments, is not flammable and has little or no smell. |

|

|||||

|

ProtectiveSheds that have been dip-treated are guaranteed against rot for 10 years, provided that they are re-coated annually with a suitable wood preservative. Re-treating your shed every year is essential to keep rot at bay, as well as to prevent the wood from drying out and warping. |

|||||