Timber treatment and guarantee |

||||||

|

||||||

|

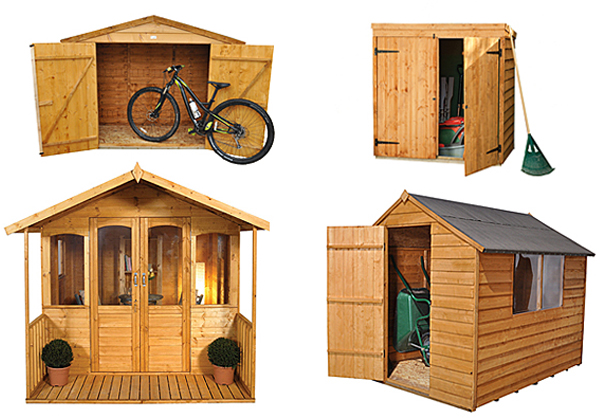

Most of Wonkee Donkee Forest Garden's products are guaranteed against rot and fungal decay for either 10 or 15 years, depending on whether they have been dip or pressure treated. This excludes the log cabins, which are delivered untreated in their raw timber state. |

||||||

Pressure-treated timber |

||||||

|

Pressure-treated timber is extremely well protected against the elements, and will last for many years. This is especially valuable if your garden structure is in direct contact with the ground, where it will be more susceptible to damp. Forest Garden uses Osmose Naturewood preservative. Trusted worldwide, this is a powerful water-based coating which contains copper and organic biocides (chemical substances that kill parasites), providing long-term protection against rot, fungus and insect attack. |

|||||

|

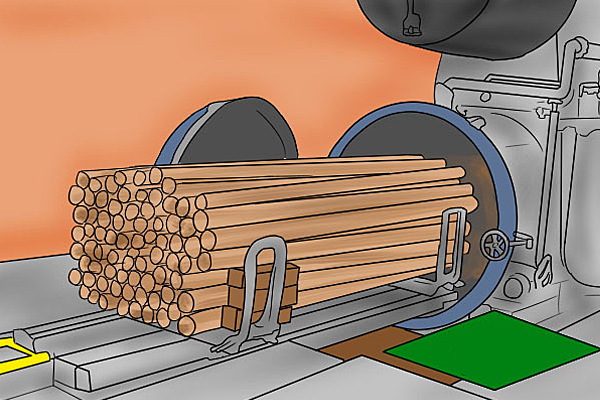

After the timber has been cut up and dried at the sawmill, it is placed in a special treatment cylinder and any remaining moisture is sucked under vacuum conditions out of the wood cells. Preservative is then forced into the timber at high pressure and absorbed into the grain so that every cell is permeated - becoming, in effect, an integral part of the wood. |

|

|||||

|

A decorative dye is added at the same time to make sure that every panel looks the same. The wood takes on a light green tinge which will gradually fade to a pale honey brown colour. There is no need to worry about the preservative becoming less effective as the colour fades - this is only due to the dye and will not affect the protective qualities of the pressure treatment. |

|||||

|

Many people prefer the natural green look of pressure-treated timber - but if you're not one of them, that's no problem. You can brush on your choice of woodstain, paint or water repellant straight away after purchase, as long as you stick to the manufacturer's instructions. |

|

|||||

|

Wonkee Donkee Forest Garden's pressure-treated products are guaranteed against rot for 15 years and will not normally require re-coating with preservative during that period, saving you time, money and effort. |

|||||

|

||||||

Dip-treated timber |

||||||

|

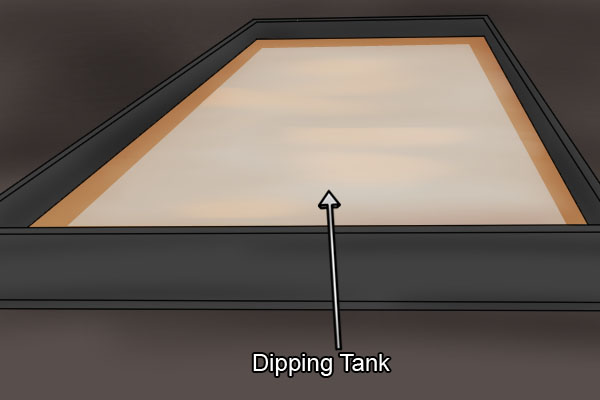

If a wooden structure is golden in colour, you can tell it has been dip-treated. This is the most common method of applying preservative to timber in bulk, and is carried out at the factory. All the wooden components that will make up the product - be it a shed, pergola or planter - are dipped into a tank of either water-based or solvent-based preservative before the pieces are put together. A cedar-red dye is applied during manufacture to ensure that every plank of wood takes on the same colour. This will gradually fade until the timber is re-treated. |

|

|||||

|

Dip-treated timber remains in demand for several reasons, the chief one being value for money. The process is quicker, simpler and less expensive to carry out than pressure treating (also known as tanalising). Labour and storage costs are lower, making this type of product popular and affordable. Its golden brown colour is pleasing on the eye, and there is a wide choice on the market. |

|||||

|

||||||

|

Wonkee Donkee Forest Garden uses water-based preservative, which is kinder to the environment than solvent-based treatments, is not flammable and emits little or no smell. Products that have been dip-treated are guaranteed against rot for 10 years, provided that they are re-coated annually with a suitable wood preservative. Re-treating your shed every year is essential to keep rot at bay, as well as to prevent the wood drying out and warping. |

|

|||||

Conditions of the anti-rot guarantee |

||||||

|

|

|||||

Log cabin treatment |

||||||

|

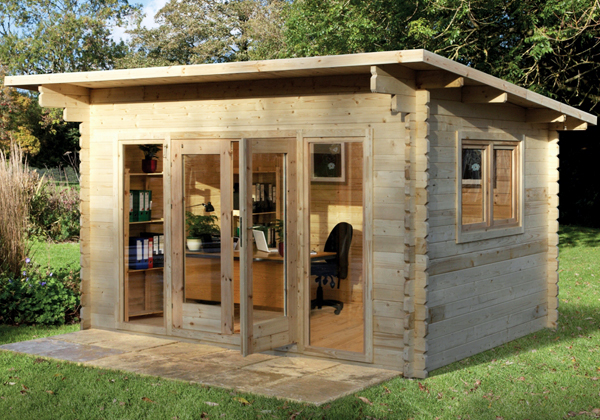

The logs used in the cabins are made from timber that has been kiln dried. This process extracts moisture to a precise level, which greatly reduces the risk of splitting and brings warping down to an absolute minimum. Pressure-treated floor bearers are supplied with every cabin to protect it from damp, but the rest of the building is delivered in its raw timber state and is untreated. |

|

|||||

|

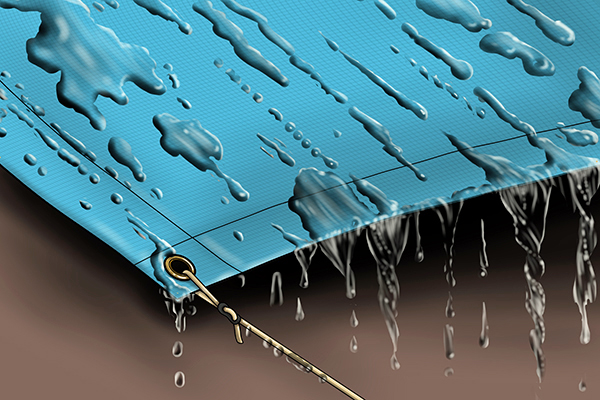

You need to apply a good quality treatment to both the interior and exterior of your cabin as soon as possible after assembly, preferably within two weeks. It's vital to make sure that the timbers stay dry and well protected until they can be treated - we recommend covering the cabin with a large, lightweight tarpaulin in case of rain. |

|||||

|

||||||

How weather affects timber |

||||||

|

As a natural product, wood is susceptible to changes in the environment. Very hot or cold temperatures or varying weather conditions will cause timber used outdoors to react. Heat may make panels lose shape but this will be reversed when the weather cools down. Pergolas and posts might warp in hotter than normal conditions. This is a completely natural process, and normal shape returns in all but the most extreme cases. Sawn wood, in particular machine-rounded items such as palisades and sleepers, may split. This will not alter the structural strength of the timber or your guarantee. As long as they are installed correctly and re-treated when necessary, Forest products will give you years of service and enjoyment. |

|

|||||

Safety tips for handling timber |

||||||

|

The preservatives contained in Osmose Naturewood are often found in a whole range of products that we use on a daily basis. Copper, an effective fungicide, is a naturally occurring mineral, and the chemical compounds it is combined with are common in everyday items such as household cleaners and disinfectants. However, it's possible that some preservative could seep from the timber into surrounding soil over a period of time, and there might be some skin contact during assembly or use, so handle with care. |

|||||

|

Just to be on the safe side we have a few recommendations:

|

|

|||||